|

|

|

|

|

HOME > 메카백과 > 메카편람 HOME > 메카백과 > 메카편람 |

|

|

|

|

|

|

|

|

제목 제목 |

표면거칠기의 적용 |

|

분류 분류 |

기계제도교실 > 표면거칠기 |

작성일 작성일 |

2006.06.20 |

|

|

작성자 작성자 |

admin   |

다운로드 다운로드 |

|

|

키워드 키워드 |

|

|

|

|

|

|

1. 가공 방법에 따른 표면거칠기 값

표 K3-1은 여러 가지 가공 방법에 따라 얻을 수 있는 표면거칠기 값을 산술평균거칠기(Ra)로 나타낸 것이다.

동일한 가공 방법에서 표면거칠기 값을 작게 할수록 표면이 고운 제품을 얻을 수 있지만, 그만큼 비용이 많이 든다는 점을 염두에 두어야 한다. |

| 가공 방법 |

표면거칠기 값(산술평균거칠기, Ra, μm) |

| 정밀 가공 |

보통 가공 |

거친 가공 |

| 사형주조(sand casting) |

|

6.3 ~ 12.5 |

12.5 ~ 25 |

| 금형주조(permanent mold casting) |

0.8 ~ 1.6 |

1.6 ~ 6.3 |

|

| 다이캐스팅(die casting) |

|

0.8 ~ 3.2 |

|

| 단조(forging) |

1.6 ~ 3.2 |

3.2 ~ 25 |

|

| 압출(extrusion) |

0.4 ~ 0.8 |

0.8 ~ 6.3 |

|

| 압연(rolling) |

0.4 ~ 0.8 |

0.8 ~ 3.2 |

|

| 셀밀링(shell milling) |

1.6 ~ 3.2 |

3.2 ~ 25 |

25 ~ 50 |

| 정면밀링(face milling) |

0.8 ~ 1.6 |

1.6 ~ 12.5 |

12.5 ~ 50 |

| 평삭 & 형삭(planing & shaping) |

|

1.6 ~ 12.5 |

|

| 선삭(turning) |

0.2 ~ 1.6 |

1.6 ~ 6.3 |

6.3 ~ 50 |

| 드릴링(drilling) |

3.2 ~ 6.3 |

6.3 ~ 25 |

|

| 리밍(reaming) |

0.4 ~ 0.8 |

0.8 ~ 6.3 |

6.3 ~ 12.5 |

| 보링(boring) |

0.2 ~ 1.6 |

1.6 ~ 6.3 |

6.3 ~ 50 |

| 원통연삭(cylindrical grinding) |

0.025 ~ 0.4 |

0.4 ~ 3.2 |

3.2 ~ 6.3 |

| 센터리스연삭(centerless grinding) |

0.05 ~ 0.4 |

0.4 ~ 3.2 |

|

| 내면연삭(internal grinding) |

0.025 ~ 0.4 |

0.4 ~ 3.2 |

3.2 ~ 6.3 |

| 평면연삭(surface grinding) |

0.025 ~ 0.4 |

0.4 ~ 3.2 |

3.2 ~ 6.3 |

| 브로칭(broaching) |

0.2 ~ 0.8 |

0.8 ~ 3.2 |

3.2 ~ 6.3 |

| 수퍼피니싱(super finishing) |

0.025 ~ 0.1 |

0.1 ~ 0.4 |

|

| 호닝(honing) |

0.025 ~ 0.1 |

0.1 ~ 0.4 |

|

| 래핑(lapping) |

0.006 ~ 0.05 |

0.05 ~ 0.4 |

|

2. 표면거칠기의 적용 예

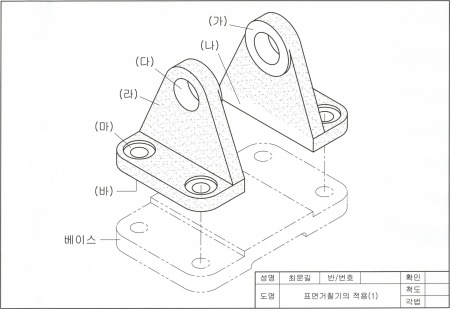

그림 K3-1 캐스터의 지지대는 주조(casting)라는 방법으로 기본 형상을 만들고 여기에 밀링, 드릴링, 리밍 등 필요한 가공을 추가하여 완성한다.

표 K3-2는 캐스터 각 부분의 가공 방법과 표면거칠기 값을 정리한 것이다. |

|

| <그림 k3-1> |

| 가공 부분 |

가공 방법 |

표면거칠기 값 |

| (가)부시와 결합되는 부분 |

밀링 |

6.3 |

| (나)베이스와 결합되는 부분 |

밀링 |

6.3 |

| (다)부시가 끼워지는 구멍 |

드릴링 후 리밍 |

1.6 |

| (라)지지대의 표면 |

주물 상태 그대로 둠 |

가공하지 않음 |

| (마)베이스와 결합하기 위해 볼트가 끼워지는 구멍 |

드릴링 후 자리 파기 |

25 |

| (바)지지대의 바닥 면으로 베이스와 결합되는 부분 |

밀링 |

1.6 |

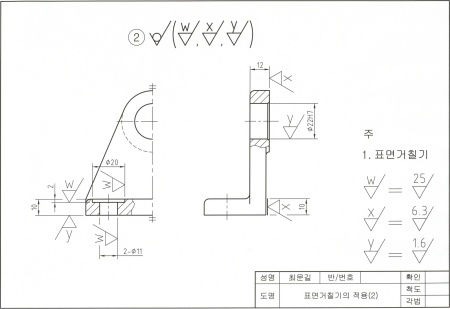

그림 K3-2는 지지대의 각 부분에 면의 지시 기호와 표면거칠기 값을 도시한 것이다.(알아보기 쉽도록 크게 그렸음)

표면거칠기 값을 알파벳 소문자 w, x, y로 대신하고 그 의미를 주(note)란에 기입하였다. 또 지시한 곳(w, x, y) 외에는 제거 가공하지 말 것을 부품 번호 옆에 표시하였다. |

|

| <그림 K3-2> |

|

|

|

|

저작권공지 : 상기자료는 사이버 제도교실 최문길 교사님이 제공하신 교육용자료로 메카피아내에서 열람만 가능하며, 원저작자의 허락없이 타사이트에 무단전재 및 복제, 기타 상업적이용시 법적인 제제를 받을 수 있으니 유의하시기 바랍니다.

|

|

|

|

|

|

|

댓글 0 개 가 등록되어 있습니다. 댓글 0 개 가 등록되어 있습니다. |

| |

|

|

|

|

|

|

|

|

| 0 /1000byte |

|

|

|

|

|

|

|

|

|

|

|

|

|